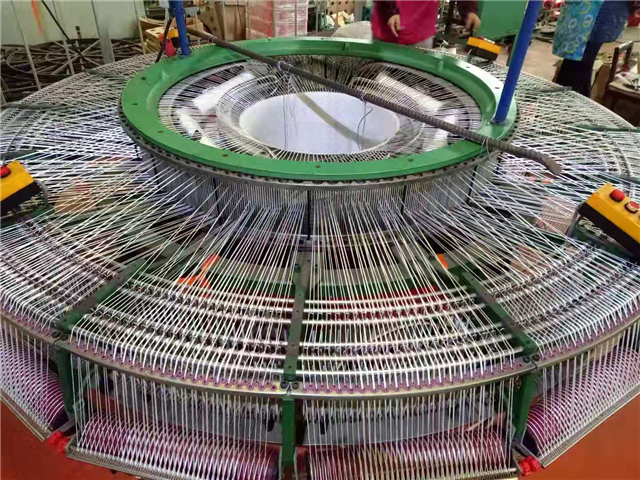

The circular loom is a machine that can continuously and efficiently produce yarn into a cylindrical braid through the warp and weft directions. The newly produced circular looms of our company are technically improved, innovated and developed. They have international advanced level and the performance indicators are obviously superior to other similar products.

This product adopts the international popular arc-shaped shuttle and breaks the traditional heald frame opening method. It uses the splitter wheel to make the splitting opening, and adds the cushioning gear to the original transmission mode, greatly improving the equipment. The smoothness and durability of the production make the product truly achieve high-speed and stable weaving.

Low noise, easy to operate, flexible and reliable, can be controlled and controlled in any part of the circular loom.

The inverter control technology can be used to control the infinitely variable speed and emergency stop brake.

Compared with foreign products, the tension roller increases the nitrile rubber layer, improves the adhesion, prevents slipping, and is more conducive to woven filament products.

The material of the main drive gear of foreign products has been improved, and the advanced high wear-resistance and self-lubricating reinforced nylon has been adopted, which greatly improves the service life.

Can be woven in a variety of forms of texture.